How to Identify Semi Truck Brake Shoes: Expert Tips Unveiled

Are you confident that your semi truck’s brakes are in top shape? Knowing how to identify semi truck brake shoes can save you from costly repairs and keep you safe on the road.

These small but crucial parts play a big role in stopping your heavy vehicle smoothly. If you’re unsure what to look for or how to spot worn-out brake shoes, this guide is made just for you. Keep reading, and you’ll learn clear, simple steps to check your brake shoes like a pro—before a small problem turns into a big one.

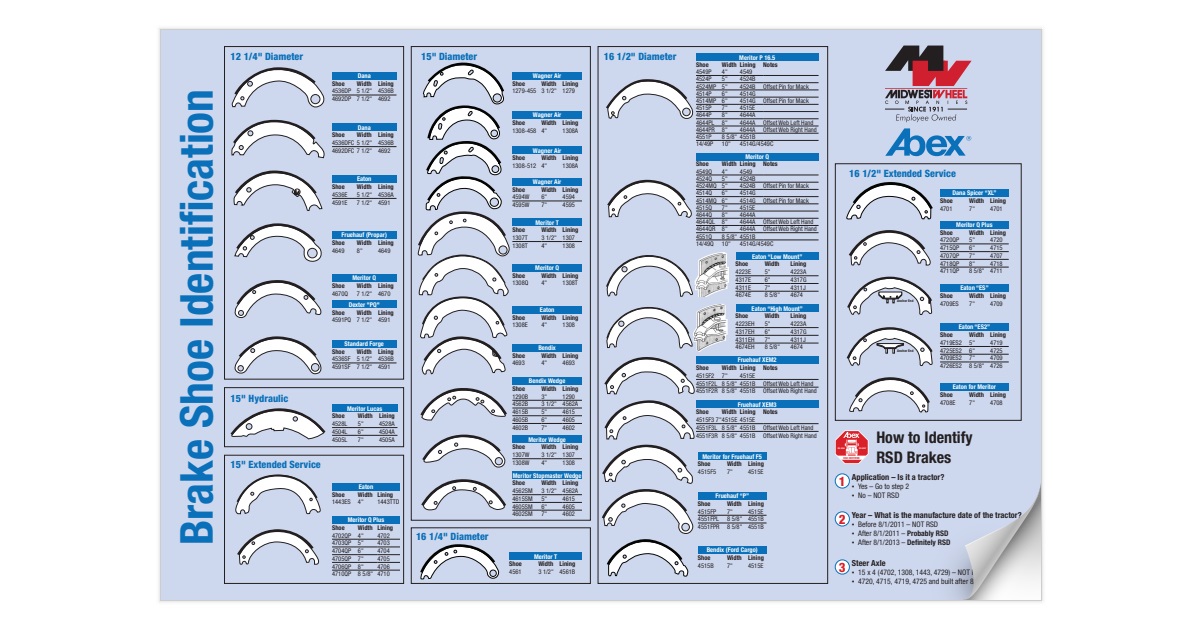

Credit: www.lonestartds.com

Types Of Semi Truck Brake Shoes

Semi truck brake shoes come in different types. Each type suits specific needs and conditions. Knowing the differences helps in choosing the right brake shoe for safety and performance.

Brake shoes vary mainly by the materials used and their design. These factors affect durability, braking power, and cost. Understanding these types makes maintenance easier and safer.

Lining Materials

Brake shoe linings are the part that touches the drum to stop the truck. Common materials include organic, semi-metallic, and ceramic.

Organic linings use natural fibers and resins. They are quiet and gentle on drums but wear faster. Semi-metallic linings mix metals with other materials. They last longer and handle heat better but can be noisier. Ceramic linings offer smooth braking and low dust. They last long but cost more.

Shoe Designs

Shoe designs affect how brake shoes fit and work. Two main designs are leading-trailing and duo-servo.

Leading-trailing shoes have one shoe that leads and one that trails. They provide balanced braking and are common in many trucks. Duo-servo shoes use two shoes that work together to increase braking force. They are more efficient but can wear unevenly.

Signs Of Worn Brake Shoes

Worn brake shoes on a semi truck can cause serious safety problems. Knowing the signs helps catch issues early. This prevents bigger damage and costly repairs. Watch for common signals your brake shoes need attention.

Noise Indicators

Squealing or grinding noises often mean brake shoes are worn out. A high-pitched sound while braking shows the lining is thin. Grinding means metal parts touch the drum. This noise needs immediate checkup. Ignoring sounds risks brake failure.

Performance Changes

Brake shoes lose efficiency as they wear down. Notice longer stopping distances or a soft brake pedal. The truck may pull to one side during braking. A vibration or shaking feeling underfoot signals problems. These changes reduce control and safety.

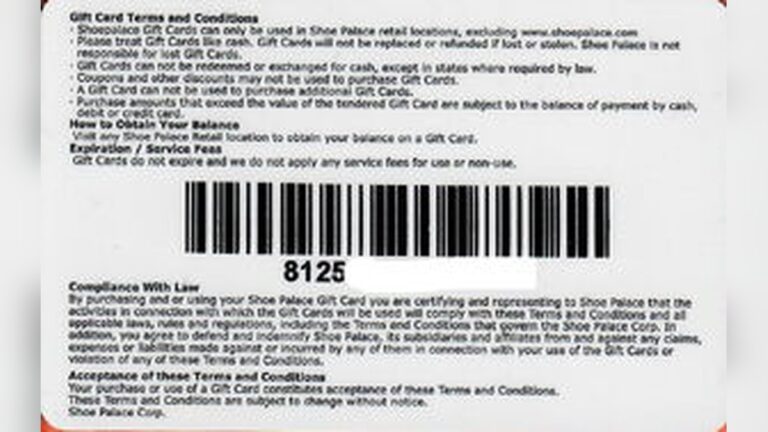

Visual Inspection Techniques

Visual inspection techniques help identify the condition of semi truck brake shoes. These techniques show wear and damage that affect brake performance. Regular checks keep brakes safe and reliable.

Focus on two key areas: thickness and surface condition. These details reveal if brake shoes need replacement or repair.

Checking Thickness

Start by measuring the thickness of the brake shoe lining. Use a ruler or caliper for accuracy. Compare the thickness to manufacturer specifications. Thin linings mean the shoe is worn out. Replace brake shoes before they become too thin.

Uneven thickness can cause braking problems. Inspect both sides of each shoe. Check multiple points along the lining. Consistent thickness ensures even brake pressure and safe stops.

Spotting Cracks And Damage

Look closely at the brake shoe surface for cracks or chips. Small cracks can grow and cause failure. Check for broken or missing pieces on the lining.

Inspect the metal backing plate too. Rust or bends reduce brake shoe strength. Damaged shoes must be replaced immediately to avoid accidents.

Clean the brake shoes before inspection. Dirt can hide damage. Use a brush or cloth to remove debris and get a clear view.

Tools For Accurate Identification

Identifying semi truck brake shoes requires precise tools. Accurate identification helps maintain safety and performance. Using the right tools reduces errors and saves time. Here are two main types of tools used for this task.

Measuring Instruments

Measuring instruments help check the size and shape of brake shoes. A caliper measures thickness and length accurately. A micrometer provides precise thickness readings. Rulers and tape measures assist with general dimensions. These tools ensure the brake shoe matches truck specifications. Correct measurements prevent fitting issues and brake failure.

Diagnostic Devices

Diagnostic devices detect brake shoe wear and condition. Brake drum micrometers measure wear inside the drum. Wear gauges show how much material remains on the shoe. Some electronic devices scan brake system health. These tools help spot problems early. They keep brakes functioning safely and efficiently.

Common Mistakes To Avoid

Identifying semi truck brake shoes correctly is important for safe driving. Many people make mistakes that cause problems later. Avoiding these errors saves time and money. Keep reading to learn common mistakes to avoid when identifying brake shoes.

Misidentifying Components

Brake shoes look similar to other brake parts. Confusing brake shoes with brake pads or drums leads to wrong repairs. Each part has a specific shape and function. Check the size and curvature carefully. Using the wrong part can cause brake failure and accidents.

Ignoring Maintenance Schedules

Brake shoes wear out over time. Not checking them regularly causes unexpected breakdowns. Follow the truck’s maintenance schedule strictly. Inspect brake shoes at every service. Timely replacement keeps brakes working well and prevents damage to other parts.

Credit: midwestwheel.com

Tips For Selecting Replacement Brake Shoes

Selecting the right replacement brake shoes for semi trucks is key to safe driving. Using the correct parts helps keep the braking system strong and reliable. Choosing the wrong brake shoes can cause poor braking or faster wear. Follow these tips to pick the best brake shoes for your truck.

Matching Specifications

Check the truck’s manual for exact brake shoe size and type. Match the thickness, diameter, and shape carefully. Different trucks need different brake shoe designs. Buy parts that fit your truck model exactly. Using wrong specifications risks brake failure and damage.

Quality Considerations

Choose brake shoes made from durable materials. Look for brands known for quality and safety. Avoid cheap parts that wear out fast. Good brake shoes last longer and improve stopping power. Inspect parts for smooth surfaces and strong linings. Quality parts protect your truck and your safety.

Credit: www.youtube.com

Frequently Asked Questions

What Are Semi Truck Brake Shoes Made Of?

Semi truck brake shoes are made from durable materials like steel and friction composites. These materials ensure long-lasting performance and heat resistance during heavy braking.

How To Check Brake Shoe Wear On Semi Trucks?

Inspect the thickness of the brake shoe lining visually or measure it with a gauge. Replace if the lining is thinner than the manufacturer’s minimum specification.

Why Is Brake Shoe Inspection Important For Semi Trucks?

Brake shoe inspection prevents brake failure and ensures safety. Regular checks identify wear or damage early, reducing costly repairs and accidents.

How Often Should You Replace Semi Truck Brake Shoes?

Replace brake shoes every 30,000 to 50,000 miles, or sooner if wear indicators show significant thinning or damage.

Conclusion

Knowing how to identify semi truck brake shoes helps keep trucks safe. Check the shape, size, and wear of the brake shoes often. Clean brake shoes work better and last longer. Pay attention to any cracks or deep grooves. Proper maintenance saves money and prevents accidents.

Always inspect brake shoes before long trips. Stay alert to sounds or smells that suggest brake problems. Taking these simple steps protects drivers and others on the road.